- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

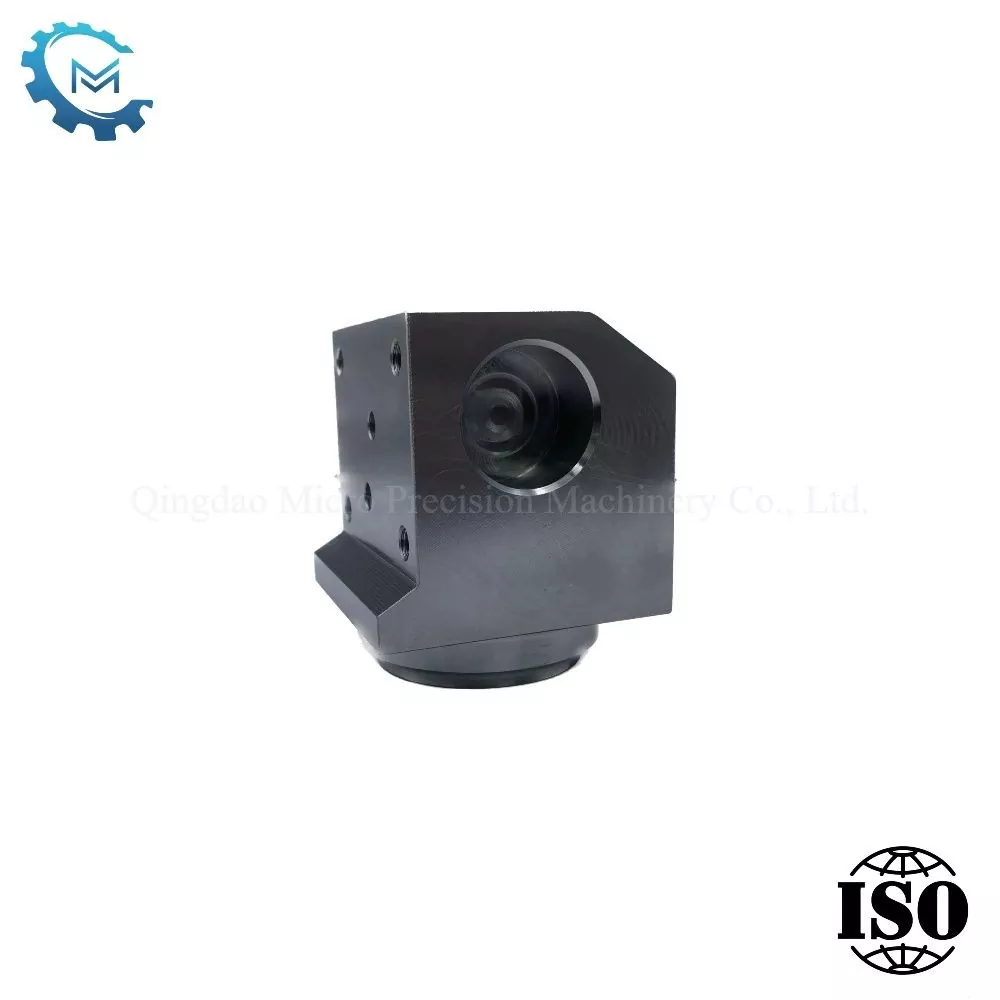

Customized Welded Cylinder Base

Customized Welded cylinder Base, also known as welded cylinder base end, is specially processed as customer's drawing and special requirement. The main function is to form an enclosed space with the cylinder to accommodate the hydraulic oil and piston assembly, while ensuring the tightness of the hydraulic cylinder, preventing oil leakage, and providing support for the piston rod and the whole hydraulic cylinder to ensure its stable work, which is similar function as common welded cylinder base.

Send Inquiry

Customized Welded cylinder base is specially processed base on customer's drawings, with speicical shape and parameters, in order to be assembled on different hydraulic cylinders or equipments.

We often produce these customized cylinder base for using in engineering machinery, metallurgical equipment, ships and other occasions, to meet different requirements of our customers.

Product parameters (or use customized parameters as clients' requirement)

|

Product Name |

Customized welded cylinder base |

|

Welded ID |

60mm |

|

Length |

80mm |

|

Width |

70mm |

|

Height |

95mm |

|

Devitation |

Inner hole H9, outer circle H9, special dimension tolerances can be customized. Others are in accordance with ISO 2768-mK. |

Function:

1. Prevent leakage of hydraulic oil

Welded to the cylinder to form a closed space to accommodate the hydraulic oil and pistonassembly, while ensuring the tightness of the hydraulic cylinder to prevent oil leakage

2. Ensure the stability when hydraulic cylinder is working

Welded cylinder base can provide support for the piston rod and the whole hydraulic cylinder to ensure its stable work. For example, in the hydraulic system of the crane, the stability of the welded cylinder bottom is crucial to the safe operation of the crane.

GET A QUOTATION NOW

Material:

High strength carbon steel or alloy steel, which is same as other hydraulic parts.

Carbon steel has low cost, could meet basic requirements; Alloy steel has high strength and good toughness, could withstand great pressure and impact force, and is suitable for using in harsh working conditions.

Processing technic:

High precision precision four-axis machine tool Process.

Use custom non-standard Tool machining to ensure the valve hole Coaxiality and finish.