- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What should I pay attention to when using cylinder seals?

2025-06-24

Introduction

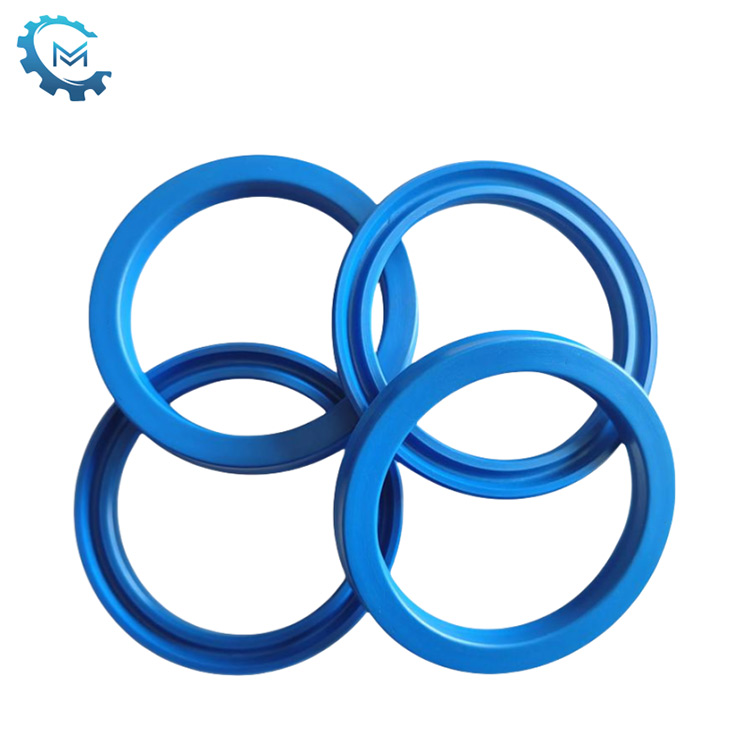

In the process of manufacturing hydraulic seals, we always provide customers with high-quality and reliable products. However, the performance and service life of the seal not only depends on its own quality, but also closely related to many factors during use. Therefore, we share some key points that customers who use seals should pay attention to during use.

1. Selection and matching

First of all, the selection of the seal is crucial. Because different seal materials and structures are suitable for different environments, for example, nitrile rubber (NBR) seals are suitable for petroleum-based hydraulic oil, lubricating oil and other media, but if in a high temperature environment, you may need to choose a fluororubber (FKM) seal with better heat resistance. We will accurately recommend suitable products to customers to ensure that the seal is perfectly matched with the equipment to avoid seal failure caused by improper selection.

2. Installation link

Installation is a key step in the use of the seal. During installation, ensure that the installation position of the seal is clean and free of impurities to avoid scratching the surface of the seal. Remember not to use inappropriate lubricants, otherwise it may damage the material of the seal and affect its sealing performance. During the installation process, operate gently to avoid excessive stretching or twisting of the seal to avoid permanent deformation of the seal, thereby reducing the sealing effect.

3. Maintenance and inspection

Even if the seal performs well in the early stage of use, regular maintenance and inspection are essential. We recommend that customers develop a reasonable inspection plan based on the frequency of use and working conditions of the equipment. During the inspection, carefully observe whether the sealing ring has signs of wear, aging, deformation, etc. At the same time, pay attention to check whether the fit between the sealing ring and the sealing cavity is loose. If there is any looseness, adjust or replace the relevant parts in time.

4. Storage conditions

For sealing rings that have not been installed or used as spares, correct storage is also important. We recommend that customers store the sealing rings in a dry, cool, well-ventilated environment, avoiding direct sunlight and high temperature baking. At the same time, be careful not to mix the sealing rings with chemicals to prevent the chemicals from corroding the sealing ring material.

Conclusion

As a manufacturer of seal rings such as glyd ring, dust ring, guide ring & oil seal , we are always committed to providing customers with high-quality products and services. We hope that by sharing the above-mentioned precautions, we can help customers better use our seal rings, ensure the safe and stable operation of the equipment, and extend the service life of the equipment.