- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

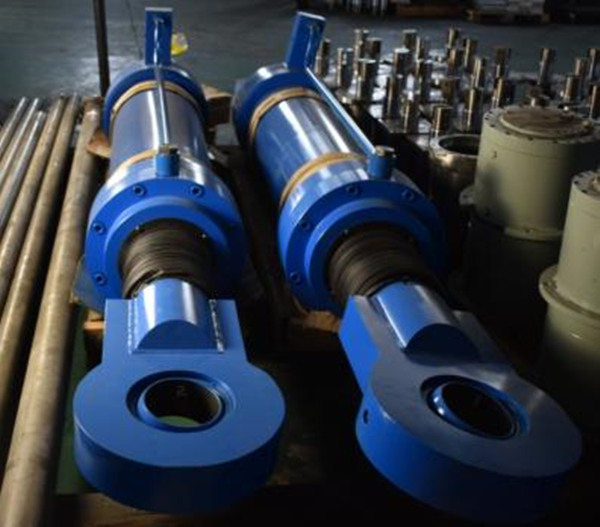

What are the challenges faced by the hydraulic cylinder industry?

2024-12-18

Introduction

With the rapid development of the hydraulic cylinder industry, it is facing a series of challenges. According to the latest market analysis and industry reports, the following are the challenges that the hydraulic cylinder industry is currently facing and may face in the future.

1. Technological Innovation

The hydraulic cylinder industry is in a period of rapid development and change, with technological innovation being a key factor in driving the industry forward. Companies need to continuously strengthen their technological research and development capabilities to improve product quality and service levels to adapt to the constantly changing market demands.

2. Market Competition

The competition in China's hydraulic cylinder market is fierce, especially in the mid-to-low-end product market. The industry concentration is relatively low, with a fragmented competitive market structure.

3. Raw Material Supply

Domestic raw materials and components cannot meet the demands of high-end hydraulic components, leading to a reliance on imported raw materials for high-end hydraulic components. The performance defects of domestic basic raw materials and components, and the insufficient supply of domestic high-end raw materials, are the main constraints on the quality improvement of high-end hydraulic products.

4. Environmental Requirements

The hydraulic components and parts manufacturing process involves process pollution, product vibration noise, material loss, and medium leakage, which have always been significant challenges for China's hydraulic industry. The industry needs to apply green manufacturing technology throughout the entire lifecycle of the products.

5. International Market Recognition

Due to the earlier start and higher overall technology level of the foreign hydraulic industry, the domestic high-end market for hydraulic components is mostly occupied by international giants. There are obstacles for domestic hydraulic component manufacturers to enter the supplier system of international mainstream manufacturers.

6. Maintenance Costs and Potential Environmental Pollution

The maintenance costs of hydraulic cylinders and their potential environmental pollution are challenges faced by the industry. In the future, the hydraulic cylinder industry will move towards more efficient, environmentally friendly, and intelligent development.

7. Research and Development Barriers

Hydraulic component manufacturers need to design and produce products according to specific customer needs, which requires companies to have strong capabilities in research and development design, production processing, and testing and detection.

In Conclusion

These challenges require companies in the hydraulic cylinder industry to continuously innovate technologically, optimize supply chain management, and improve product quality and service levels to cope with the dual pressures of the market and the environment.