- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What are the causes and effects of excessive oil temperature in the hydraulic system?

2024-12-17

Introduction

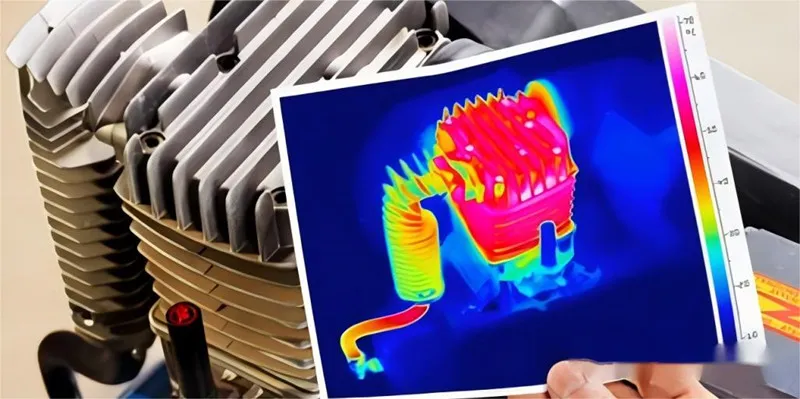

Hydraulic systems tend to generate heat during operation, especially when under high load or long-term operation, the hydraulic oil temperature tends to rise. Excessive oil temperature not only affects the performance of the system, but also accelerates the wear of components and even causes early failure of equipment. Therefore, a deep understanding of the factors affecting hydraulic oil temperature, the negative impact of excessive oil temperature on the system, and effective temperature management strategies are essential to ensure efficient and stable operation of the hydraulic system.

1. What Causes Hydraulic System Oil Temperature Too High?

The root cause of high oil temperature is that the accumulation of heat in the hydraulic system exceeds the system's heat dissipation capacity. The following are the main causes of high oil temperature in the hydraulic system:

(1) Insufficient Heat Dissipation

The heat in the hydraulic system mainly comes from internal friction and pressure loss. When the heat dissipation devices such as coolers and radiators fail to discharge this heat in time, the oil temperature will gradually rise. Failure or improper design of cooling equipment will lead to insufficient heat dissipation.

(2) Improper Selection Of Hydraulic Oil Viscosity

If the viscosity of the hydraulic oil is too high or too low, it will affect the normal operation of the system. If the viscosity is too high, it will increase the flow resistance of the oil and cause the oil temperature to rise; if the viscosity is too low, it will reduce the lubrication effect, increase the friction of the system, and generate more heat.

(3) Excessive System Load And Pressure

Long-term high load or high pressure operation will cause excessive friction and stress on the components in the system, generating a lot of heat. If the system runs under high load for a long time and cannot effectively dissipate heat, the oil temperature will continue to rise.

Hydraulic component wear and internal leakage

Wear of components such as hydraulic pumps, valves and actuators can cause internal leakage, which converts energy loss into heat, causing the oil temperature to rise. As the components age, internal leakage will increase, further increasing the system temperature.

(4) Oil Contamination

Hydraulic oil contamination can lead to reduced oil performance and increased friction and drag. The accumulation of contaminants such as impurities, moisture and oxidation products will change the viscosity of the oil, reduce its cooling and lubricating capabilities, and thus increase the oil temperature.

(5) Return Oil Flow Rate Is Too Fast Or Too Slow

The flow rate of hydraulic oil in the system will also affect the temperature. Too high a flow rate will increase the friction inside the system and generate additional heat, while too low a flow rate may lead to poor oil circulation, poor cooling effect, and difficulty in reducing the oil temperature.

2. Effects Of High Oil Temperature

Excessive oil temperature in the hydraulic system will bring a series of negative effects, affecting the performance, reliability and life of the system. The following are the main effects of excessive oil temperature on the hydraulic system:

(1) Oil Viscosity Decreases

As oil temperature increases, the viscosity of hydraulic oil decreases, resulting in a weakened lubrication effect in the hydraulic system, increased friction and wear, and reduced component life. In addition, decreased viscosity can also lead to increased internal leakage of hydraulic components and reduced system efficiency.

(2) Aging Of Seals

Long-term high-temperature operation will accelerate the aging, hardening and deformation of rubber seals, reduce the sealing effect, cause hydraulic oil leakage, and thus affect system performance.

(3) Damage To Hydraulic Components

High temperature may aggravate the wear of the surface of hydraulic components, leading to premature failure of key components such as piston rods and hydraulic pumps. At the same time, long-term high-temperature operation may also lead to degradation of metal material performance, such as weakened strength and fatigue failure.

(4) Oil Oxidation And Deterioration

Excessive oil temperature will accelerate the oxidation of hydraulic oil, produce sludge, acidic substances and other impurities, and cause hydraulic oil deterioration. Deterioration of the oil will affect the lubricity, cooling and cleanliness of the system, and further damage the hydraulic components.

(5) System Efficiency Decreases

When the oil temperature is too high, the pressure loss of the hydraulic system increases and the efficiency of the components decreases. For example, the output capacity of the pump decreases, the response speed of the actuator slows down, and the overall efficiency of the system decreases.

In Conclusion

An effective oil temperature management strategy is critical to the proper functioning of your hydraulic system. Here are some key temperature management methods:

(1) Temperature Monitoring And Early Warning System

Install temperature sensors and monitoring devices to monitor the temperature of hydraulic oil in real time. Establish temperature thresholds and alarm mechanisms to detect abnormal oil temperature in a timely manner and take measures. Through real-time monitoring of temperature data, operators can detect potential problems early and avoid failures caused by excessive temperature.

(2) Regular Maintenance And Care

Regularly check the system's cooling equipment, oil tank, filter and pipelines to ensure that the system is operating normally. Especially under high-load conditions, timely cleaning and replacement of aging or damaged components can effectively prevent the occurrence of excessive oil temperature problems.

(3) Choose The Right Hydraulic Oil

According to the system's working environment and requirements, choose high-quality hydraulic oil with good thermal stability and high viscosity index. High-quality oil can maintain good lubrication performance at high temperatures and reduce problems caused by temperature fluctuations. In addition, regular oil changes to prevent oil deterioration are also important temperature management measures.

(4) Optimize Workload And Energy Management

By properly arranging the workload of the system, avoid long-term high-load operation. Selecting the appropriate size of pumps, valves and actuators to reduce energy losses in the system can effectively reduce heat generation. By improving the energy efficiency of the system, reducing temperature fluctuations, and maintaining smooth operation of the system.