- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Industry News

How to match hydraulic cylinder seals?

As a hydraulic cylinder manufacturer, we know the importance of seals in hydraulic cylinders. Reasonable matching of seals can not only effectively prevent hydraulic oil leakage, but also extend the service life of the hydraulic cylinder and improve the performance of the entire hydraulic system.

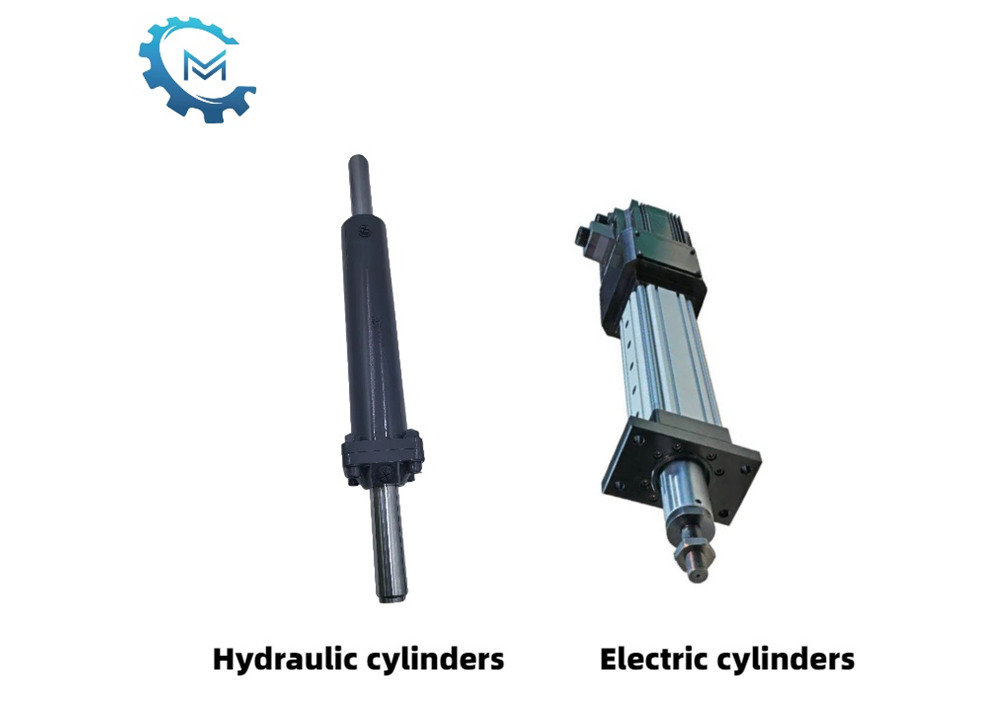

Read MoreHydraulics vs Electrics: Which is Better for Heavy Machinery?

In heavy-duty fields such as construction machinery and mining equipment, the choice of power system directly determines the performance, efficiency and sustainability of the equipment. In recent years, the competition between hydraulic technology and electrification solutions has become increasingl......

Read MoreShould the relief valve be installed before or after the check valve?

As a hydraulic equipment manufacturer, we often think about the installation order of relief valves and check valves when designing hydraulic systems. Both valves play an important role in hydraulic systems. The relief valve is mainly used to protect the system from damage caused by excessive pressu......

Read MoreHow do I identify my hydraulic cylinder?

Hydraulic cylinders are key actuators in hydraulic systems, and their correct identification is crucial for equipment maintenance, selection, and troubleshooting. As a professional hydraulic cylinder manufacturer, we will introduce to you in detail how to identify our hydraulic cylinders.

Read MoreDoes a bigger hydraulic cylinder make a difference?

The selection of hydraulic cylinder size has always been a hot topic in the industry. As a manufacturer of hydraulic cylinders, we have accumulated rich experience in the production and application of hydraulic cylinders. We know that the larger the hydraulic cylinder, the better, but should be accu......

Read MoreWhat is the difference between a round flange and a square flange?

In our daily work as flange manufacturers, round flanges and square flanges are two common product types. They each have unique designs, manufacturing processes and application scenarios. The following is our company's analysis and comparison of these two flanges.

Read More