- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Industry News

How much do you know about CNC machine tool accessories?

In modern manufacturing, CNC machine tools are undoubtedly the core force in the processing field, but the role of machine tool accessories should not be underestimated. They are also an indispensable part of machine tool processing operations.

Read MoreDo you know the performance of hydraulic oil?

Hydraulic oil is a large category of industrial lubricants. It can be petroleum-based, water-based or composed of other organic substances. Hydraulic oil is used as an intermediate medium in hydraulic transmission systems. In addition to transmitting and converting energy, it also plays the role of ......

Read MoreHow to choose high-precision accessories suitable for CNC machine tools?

As the core equipment for precision machining, the machining accuracy of CNC machine tools is directly related to product quality. In order to achieve high-precision operation, in addition to the excellent performance of the machine tool itself, its matching accessories are also indispensable. Below......

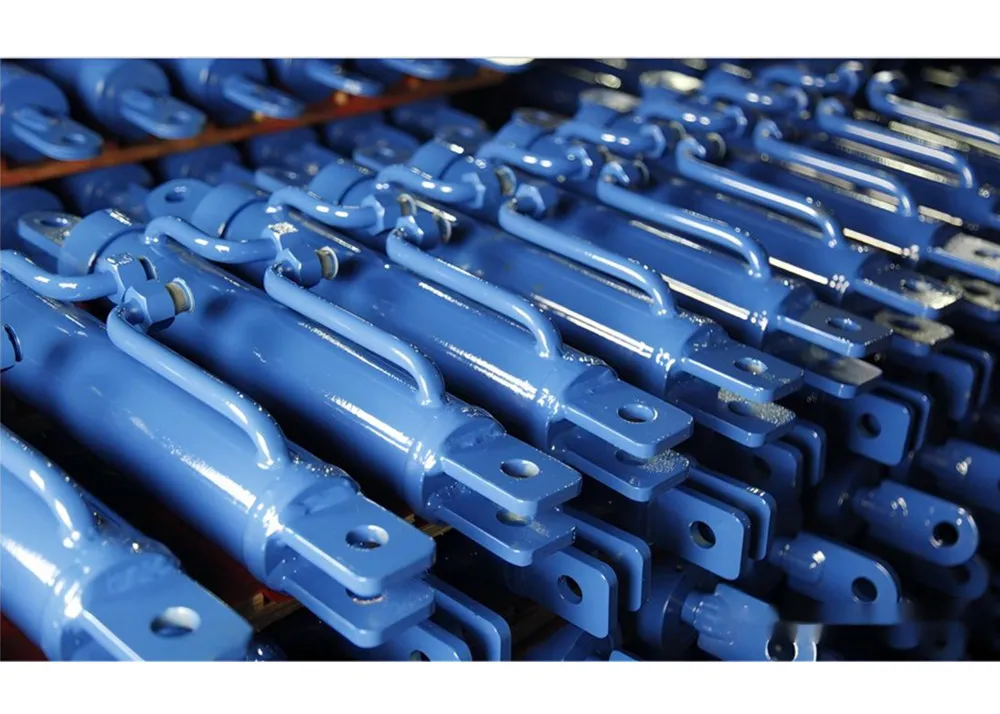

Read MoreHow To Disassemble And Assemble The Hydraulic Cylinder And What Precautions Should Be Taken?

The disassembly and assembly of hydraulic cylinders is a process that requires careful operation and involves multiple steps and precautions. To ensure the safety and efficiency of the disassembly and assembly process, it is necessary to follow the correct steps.

Read MoreWhy do hydraulic cylinders change color on excavators?

In the daily operations of excavators, hydraulic cylinders, as a key actuator, directly affect the work efficiency of the excavator. However, the color change of hydraulic cylinders is a common issue that has drawn the attention of operators and maintenance personnel.This color change process is not......

Read More