- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What Are The Different Types Of Stainless Steel Wire For Precision Engineering

2025-10-30

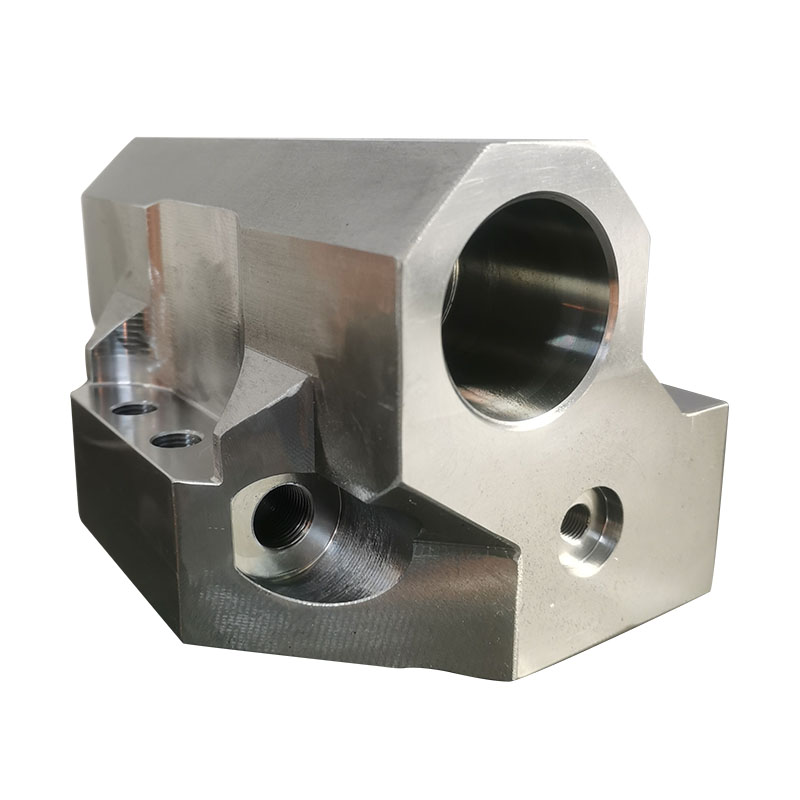

I have spent the better part of my career in the Micro Precision Machinery industry, and if there is one thing I have learned, it is that the foundation of any reliable component is its raw material. We often get questions not just about our complex assemblies like the Hydraulic Valve Block, but about the fundamental elements that make them function. A common query we tackle is about the types of stainless steel wire we use and why the specific grade matters so much.

So, what are the different types of stainless steel wire, and how do you choose the right one for an application that demands zero failure

Why Does the Grade of Stainless Steel Wire Even Matter

Think of stainless steel wire as the central nervous system of many mechanical assemblies. It might not be the largest component, but its failure can paralyze an entire system. In our world of Micro Precision Machinery, we are not making paperclips. We are crafting critical components where tensile strength, corrosion resistance, and fatigue life are non-negotiable.

Using an incorrect grade can lead to catastrophic downtime. Imagine a Hydraulic Valve Block failing on an offshore oil rig because a retaining ring made from a low-grade wire succumbed to saltwater corrosion. Or a medical device malfunctioning because a spring lost its tension. The grade dictates performance, longevity, and ultimately, the safety of the entire system. This is why our material selection process is so rigorous.

What Are the Primary Stainless Steel Wire Grades We Use

We primarily work with three families of stainless steel wire, each engineered for a specific set of challenges. The choice depends entirely on the operational environment and the mechanical demands of the part.

-

Austenitic (300 Series): This is the most common family, known for its excellent corrosion resistance and formability.

-

Martensitic (400 Series): These grades can be heat-treated to achieve very high strength and hardness.

-

Precipitation-Hardening (PH Series): These offer a unique combination of high strength and good corrosion resistance.

To help you visualize the core differences, here is a breakdown of the key grades we specify daily.

| Grade Family | Common Grades | Primary Characteristics | Best For Applications Involving |

|---|---|---|---|

| Austenitic | 304, 316, 302 | Excellent corrosion resistance, good high-temperature performance, non-magnetic | Medical devices, food processing, marine environments, chemical exposure |

| Martensitic | 410, 420, 440 | High strength, good wear resistance, magnetic | Springs, fasteners, cutting tools, high-stress mechanical parts |

| Precipitation-Hardening | 17-7PH, 630 | Very high strength-to-weight ratio, good corrosion resistance | Aerospace components, high-performance springs, critical Hydraulic Valve Block components |

How Do You Match the Wire Properties to Your Application

Knowing the grades is one thing, but selecting the right one requires a deep dive into the technical parameters. It is not just about picking 304 because it is common. For instance, a Hydraulic Valve Block operating in a standard industrial setting might use 304 components, but one destined for a chemical plant would require the superior chloride resistance of 316.

We have built our reputation at Micro Precision Machinery on getting this selection perfect every time. Here is a more detailed look at the properties we control.

| Parameter | Why It Matters | How We Ensure Precision at Micro Precision Machinery |

|---|---|---|

| Tensile Strength | Determines the wire's resistance to breaking under tension. Critical for springs and load-bearing clips. | We specify and verify tensile strength for every batch, ensuring it meets the narrow band required for your part. |

| Diameter Tolerance | A variation of a few microns can cause failure in a tightly toleranced assembly. | Our drawing process maintains diameters with tolerances as tight as ±0.0005mm for critical applications. |

| Corrosion Resistance | Defines how the wire will perform in harsh environments, resisting rust and pitting. | We match the grade to the environment, often going beyond standard grades to specialty alloys for extreme conditions. |

| Surface Finish | Affects friction, wear, and the potential for micro-cracks that lead to fatigue failure. | We offer a range of finishes, from a bright drawn to a specialized matte finish, to ensure optimal performance in your Hydraulic Valve Block. |

Your Hydraulic Valve Block FAQ Answered

We know that when you are sourcing components, you have specific questions. Here are some of the most common ones we get about the use of wire in Hydraulic Valve Block systems.

What is the best stainless steel wire for a high-pressure Hydraulic Valve Block spring

For most high-pressure applications, we recommend 17-7PH or 302 stainless steel. 17-7PH is superior because it can be precipitation-hardened to achieve an exceptional balance of very high tensile strength and good corrosion resistance, which is essential for handling intense pressure cycles without deforming or failing.

Can you supply custom-formed wire components for a specialized Hydraulic Valve Block

Absolutely. This is a core specialty of Micro Precision Machinery. We take the precisely manufactured wire and use advanced CNC coiling and forming machines to create custom springs, seals, and retention clips that integrate directly into your Hydraulic Valve Block design. We work from your blueprints or can assist in designing the component for optimal performance.

How does wire corrosion inside a Hydraulic Valve Block lead to system failure

Corrosion is a silent killer. If a wire-formed component like a spring or a clip inside the block begins to corrode, it can shed particulate matter into the hydraulic fluid. This debris can travel through the system, clogging small orifices and scoring valve spools, leading to a loss of pressure control, leaks, and eventual complete system seizure. Using a corrosion-resistant grade matched to the hydraulic fluid and external environment is critical.

Are You Ready to Specify the Right Wire for Your Project

Choosing the right stainless steel wire is not an academic exercise, it is a critical engineering decision that impacts the reliability, safety, and cost of your final product. At Micro Precision Machinery, we do not just sell wire, we provide engineered solutions. We partner with you to analyze your application, from the operating environment to the peak load cycles, to ensure the material specified is the best possible fit.

Do not let a minor component be the point of failure in your major system. Contact us today with your specifications, and let our two decades of material science expertise bring unparalleled precision and reliability to your next project, especially when it comes to the heart of your system—the Hydraulic Valve Block.