- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

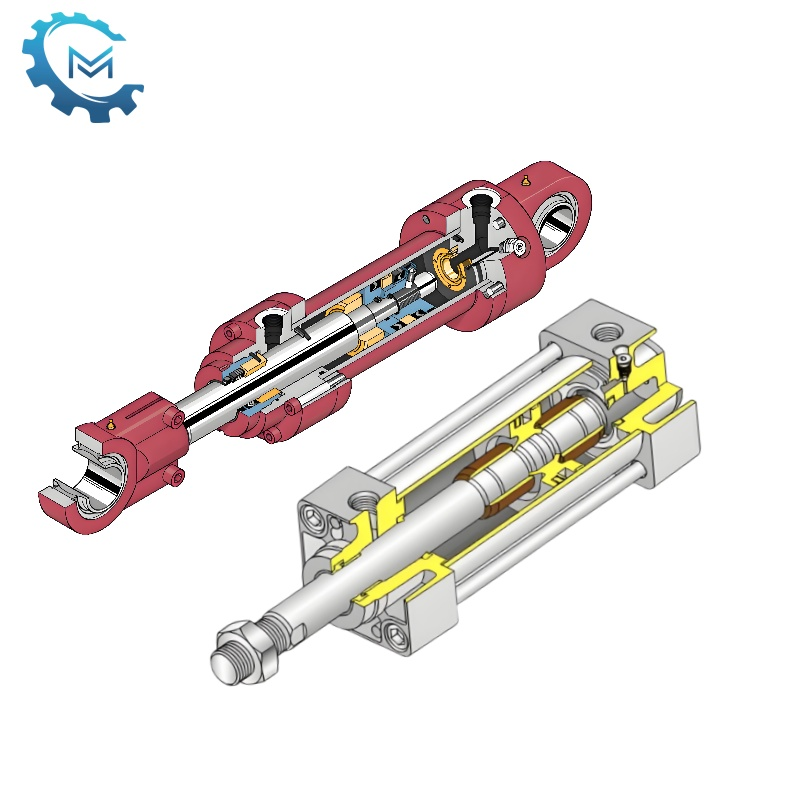

What are the differences between hydraulic cylinders and pneumatic cylinders?

Introduction

As a manufacturer specializing in the manufacture of hydraulic systems, we would like to discuss the essential differences between these two types of hydraulic oil cylinders and pneumatic cylinder actuators based on our many years of production experience.

The difference between hydraulic cylinder and pneumatic cylinder.

1. Different power sources

Hydraulic cylinders rely on hydraulic oil as a transmission medium, while pneumatic cylinders use compressed air. This fundamental difference determines their differences in performance, structure, and application scenarios.

From our point of view, hydraulic cylinders require higher sealing and pressure resistance. We usually use high-strength steel and precision seals to ensure that there is no oil leakage under high pressure (even up to 30MPa or more). However, due to the low working pressure of the cylinder (generally between 0.3~1.0MPa), the requirements for materials are relatively loose, and the manufacturing cost is also lower.

2. Output force and control accuracy

The advantages of hydraulic cylinders are large output force and high control accuracy. When we design hydraulic systems, we can achieve precise force control and speed adjustment by adjusting the oil pressure, which is suitable for heavy-load, high-precision industrial scenarios, such as metallurgy, mining, engineering machinery, etc.

Although pneumatic cylinder has a fast response speed, due to the compressibility of air, the control accuracy is relatively low, which is suitable for light-load, high-speed, and frequent start-stop occasions, such as automated assembly lines, packaging machinery, etc.

3. Structural complexity and maintenance cost

From the perspective of manufacturing and maintenance, the hydraulic system structure is more complex. Hydraulic cylinders usually require supporting pump stations, oil tanks, oil filters, cooling systems, etc. We also conduct strict oil cleanliness and sealing tests before leaving the factory.

In contrast, the pneumatic cylinder system has a simple structure, easy installation, and low maintenance cost. Customers only need to connect to the air source to use it, which is one of the reasons why it is popular in light industry.

4. Environmental adaptability and safety

The hydraulic system performs more stably in harsh environments such as high temperature, high humidity, and dust. When designing, we will consider factors such as dustproof, waterproof, and corrosion-resistant to ensure that the hydraulic cylinder can operate reliably under extreme conditions.

And pneumatic cylinders have more advantages in explosion-proof and clean environments. Because the air is pollution-free and there is no risk of sparks, we recommend customers to use cylinders in these areas.

Conclusion

As a manufacturer, we do not think that hydraulic cylinders or pneumatic cylinders are better or worse, but we should choose the most suitable product according to the customer's specific application scenarios. We always recommend that customers clarify the load requirements, control accuracy, environmental conditions and budget range before selecting a model, so that they can make the best decision.