- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Which clamp has the longest life?

2025-06-05

Introduction

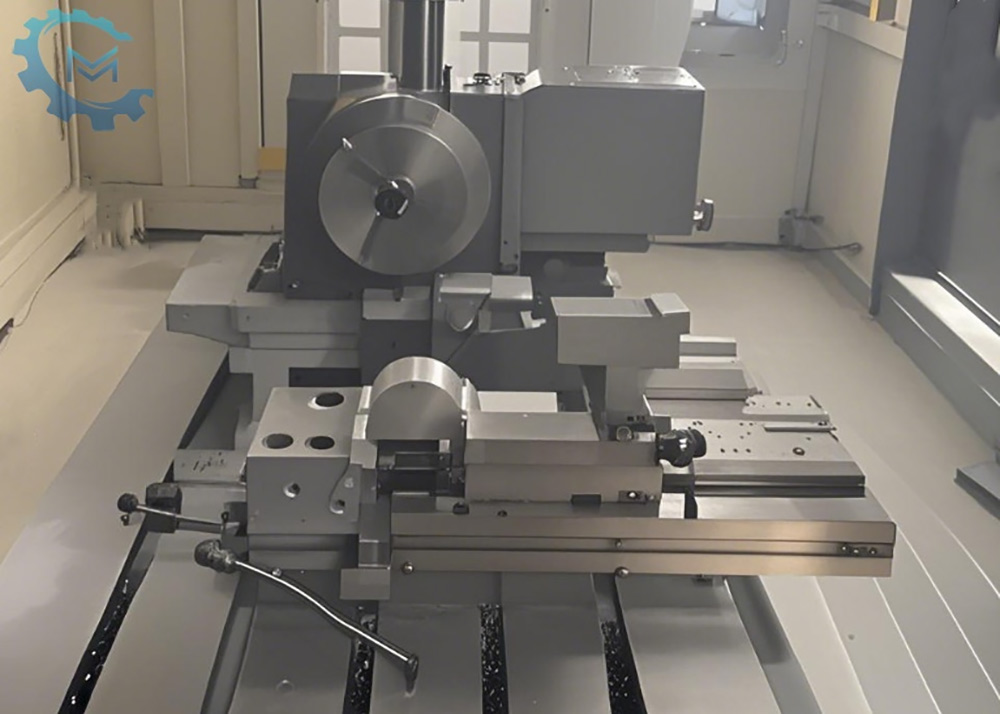

In the manufacturing industry, the clamp is the "hand" of the machine tool, which directly affects the processing accuracy, efficiency and cost. However, the clamp will lose accuracy and malfunction frequently after a short time. Frequent replacement is not only expensive, but also delays production. So, which clamp is truly durable and with strong clamping force? It is undoubtedly the vise.

Why are ordinary clamps easily damaged?

1. Improper material selection: In order to reduce costs, fixtures often use ordinary steel or even cast iron. After long-term exposure to large clamping forces and repeated friction, they are prone to wear and deformation, which leads to loss of precision due to long-term accumulation and directly affects the processing tolerance.

2. Unreasonable design: During the production process of ordinary fixtures, their key parts are often not finely ground and heat treated, which to a certain extent affects the overall performance of the fixture.

3. Insufficient maintenance: Even high-quality fixtures will have their service life shortened due to problems such as drying of lubricating oil and loose parts if they lack regular inspection and maintenance.

Why hydraulic vises are durable?

1. Application of high-rigidity materials

The body of the hydraulic vise is made of high-strength steel with a hardness of HRC54. The tensile strength is more than twice that of ordinary cast iron body. Even under extreme working conditions, the structure can remain intact and is not easily deformed or damaged. The base is made of high-speed steel with a hardness of up to HRC56°, and the wear resistance is 40% higher than that of ordinary tool steel. Even with long-term continuous processing, the parallelism error of the jaws can be maintained at ≤0.02mm.

2. Precision design and manufacturing

In order to further improve the durability of the hydraulic vise, the body design of the hydraulic vise adopts the integral steel hollowing process. This process ensures that the body has a good internal support structure, which not only reduces weight but also maintains strength, and effectively avoids cracks or fractures caused by local stress concentration. The sealing components in the hydraulic system are made of imported high-quality materials and have been strictly tested to ensure long-term work without leakage. This not only improves work efficiency, but also reduces the need for maintenance due to sealing problems.

3. Independently replaceable modular design

The hydraulic station, vise and other components are packaged independently. When a component is damaged, there is no need to replace the entire fixture. For example, when the jaws are worn, only the jaws need to be replaced, reducing costs by 70%.

Conclusion

As a manufacturer of hydraulic vises, we are committed to continuous improvement and innovation of products to meet the growing needs of users. We understand that the reason why hydraulic vises are so popular in the clamp market is inseparable from their excellent service life and reliable performance. In the future, we will continue to increase R&D investment, optimize product design, and improve manufacturing technology to provide users with more efficient, durable and precise hydraulic vises.