- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Hydraulic Solenoid Valves - In-depth Analysis from Manufacturers

2025-05-13

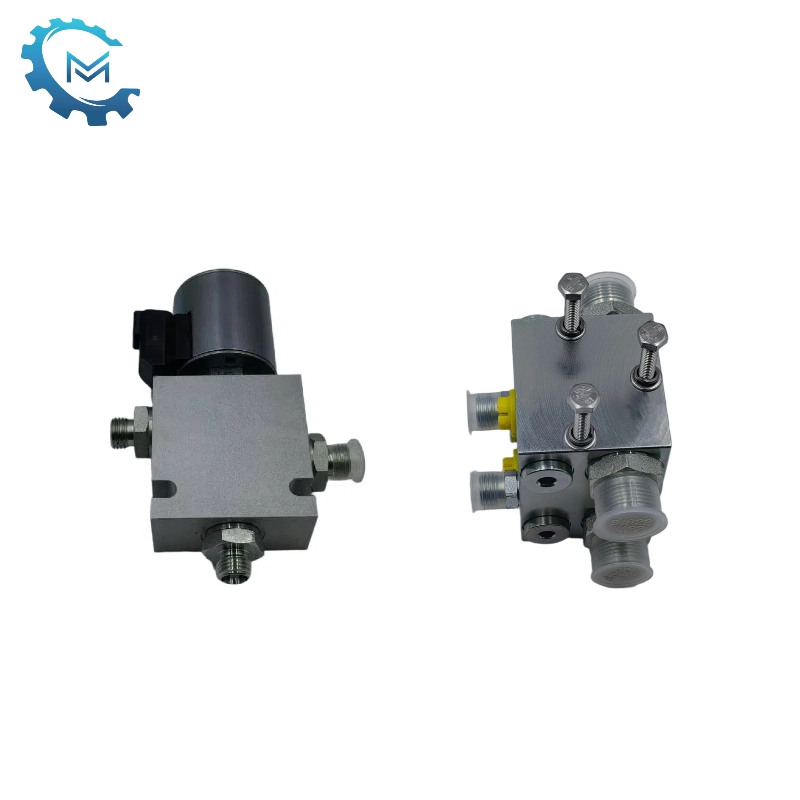

In the hydraulic system, the hydraulic solenoid valve accurately controls the flow direction and pressure of the oil to ensure that the entire system can operate efficiently and stably. As a company specializing in the manufacture of hydraulic solenoid valves, we would like to talk to you about hydraulic solenoid valves from the perspective of a manufacturer.

1. Structure and principle of hydraulic solenoid valve

Hydraulic solenoid valve is the product of combining electromagnetic control technology with hydraulic technology. It is mainly composed of electromagnetic coil, valve core, valve body and spring. When the electromagnetic coil is energized, a magnetic field will be generated, which will attract the valve core, thereby changing the position of the valve core and controlling the flow direction of the oil. We carefully select high-strength and corrosion-resistant materials to manufacture the valve body to ensure that it can operate stably in various harsh working environments. The valve core is the core of the hydraulic solenoid valve, and its precision and surface quality directly affect the performance of the solenoid valve. We use advanced processing technology to control the accuracy of the valve core at the micron level to ensure its sealing with the valve body during movement, so as to ensure that the flow direction and flow of the oil can be accurately controlled.

2. Types and applications of hydraulic solenoid valves

There are many types of hydraulic solenoid valves, which can be divided into many types. In terms of function, there are reversing valves, overflow valves, pressure reducing valves, etc.; in terms of control mode, there are direct-acting and pilot-operated types; in terms of working voltage, there are AC, DC and other types. Each type of hydraulic solenoid valve has its unique application scenario.

The reversing valve is one of the most common solenoid valves in hydraulic systems. It is mainly used to control the flow direction of oil. In engineering machinery, hydraulic machine tools and other equipment, the reversing valve can quickly and accurately change the movement direction of the hydraulic cylinder or hydraulic motor. The overflow valve is mainly used to control the pressure in the hydraulic system. It can ensure that the system pressure does not exceed the set value and protect the system. In some high-pressure hydraulic systems, the overflow valve can effectively prevent equipment damage caused by excessive pressure. The pressure reducing valve is used to reduce the pressure of a certain part of the hydraulic system to meet the different pressure requirements of different components.

The direct-acting hydraulic solenoid valve has a simple structure and fast response speed, but the diameter is relatively small, which is suitable for hydraulic systems with small flow. The pilot hydraulic solenoid valve controls the movement of the main valve core through the pilot valve, which can achieve large diameter and large flow control, and is suitable for hydraulic systems with medium and large flow.

3. Manufacturing process and quality control of hydraulic solenoid valves

From the beginning of raw material procurement, we have established a strict supplier screening mechanism and only cooperate with suppliers with good reputation and reliable quality. Each batch of raw materials must undergo strict quality inspection before entering the factory, and only qualified raw materials can be used for production. During the production process, we use advanced processing equipment and processes, such as high-precision CNC machining centers, advanced surface treatment processes, etc., to ensure the processing accuracy and quality of each component. For key components, such as valve cores and valve bodies, we will also conduct multiple inspections and tests to ensure that their performance meets the design requirements.

4. After-sales service of hydraulic solenoid valves

Although the hydraulic solenoid valve has a compact structure and reliable performance, it may also fail for various reasons during actual use. Therefore, we provide customers with a full range of after-sales services to ensure that customers have no worries during use.

Conclusion

In summary, as a manufacturer, we always adhere to customer-centricity, and provide customers with high-quality hydraulic solenoid valve products through exquisite manufacturing technology, strict quality control and perfect after-sales service. We look forward to cooperating with more customers to jointly promote the development and application of hydraulic technology.